With the rapid advancement of technology, artificial intelligence (AI) has been increasingly applied across various industries. In particular, AI color sorters have become essential tools for enhancing productivity and ensuring product quality in agriculture and food processing due to their high efficiency, precision, and automation capabilities. Especially in the processing of hazelnuts and other nuts, AI color sorters utilize high-precision sorting systems to accurately separate defective products, such as wormhole hazelnuts, thereby improving product quality and market competitiveness.

Wormhole hazelnuts are a common quality issue in hazelnuts, usually caused by insect infestation during the growth process. The presence of wormholes not only affects the appearance of the hazelnuts but may also reduce their taste and nutritional value. In traditional sorting processes, manual inspection is often inaccurate, it easy to overlook hazelnuts that appear intact on the surface but contain wormholes. This can compromise the overall quality of an entire batch.

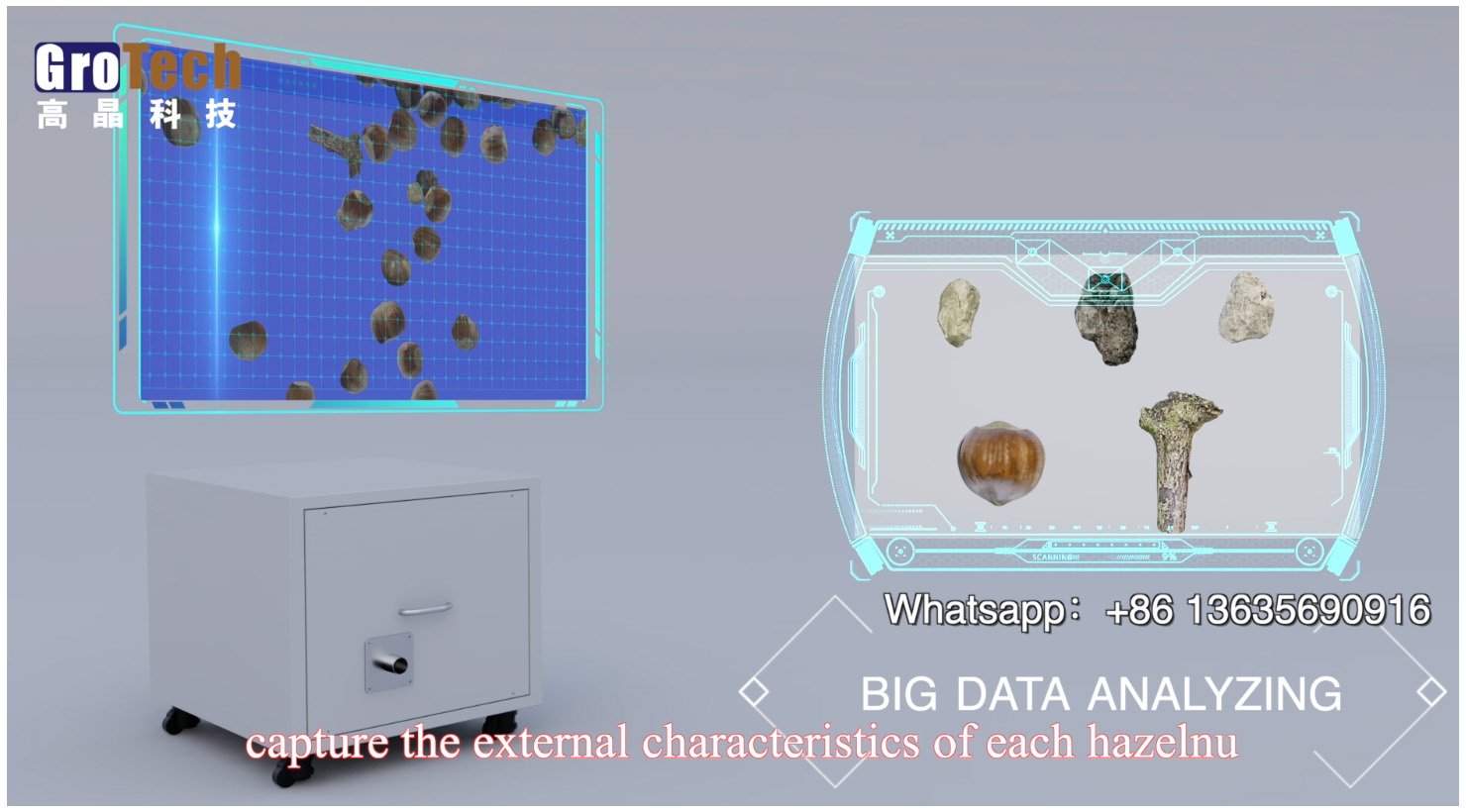

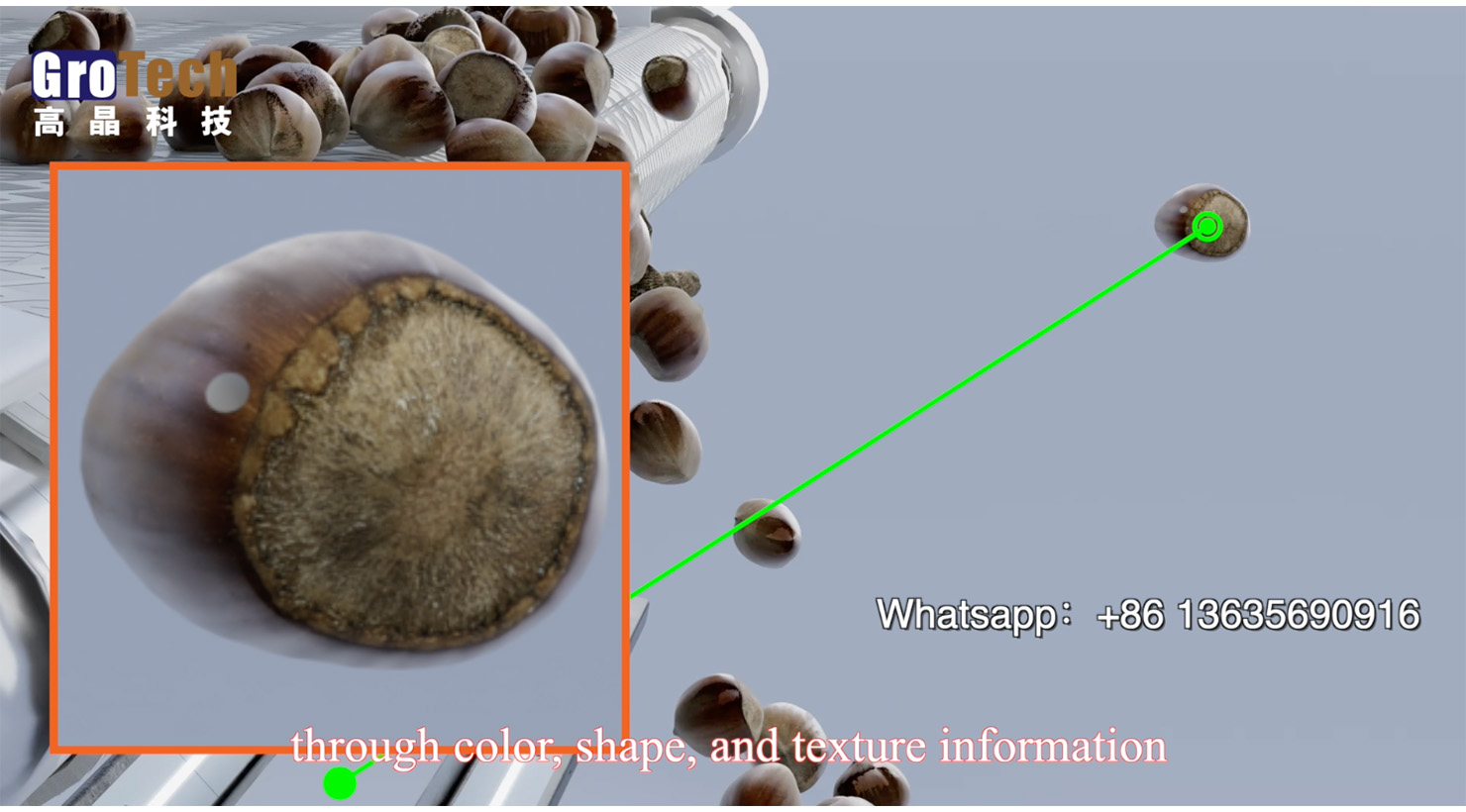

AI color sorters utilize artificial intelligence and machine vision technology to precisely scan and analyze hazelnuts. The fundamental principle involves using high-resolution cameras and image processing technology to capture the external characteristics of each hazelnut and compare them with a database of standard hazelnut features. AI color sorters can quickly identify defects, such as wormholes, based on color, shape, and texture information and then remove these defective hazelnuts from the qualified products using an airflow sorting system.

The greatest advantage of AI color sorters lies in their high degree of automation and recognition accuracy. During the sorting process, AI systems continuously optimize recognition models through deep learning algorithms, enabling them to automatically detect wormhole-infested hazelnuts from a vast quantity of nuts. This approach not only reduces labor costs but also significantly enhances sorting efficiency while minimizing human error.

During operation, high-speed cameras capture the surface characteristics of each hazelnut and input the data into the AI system. The system then analyzes potential wormholes, scars, or discoloration. With the help of an air-jet ejection system, the AI color sorter precisely separates these defective nuts from the high-quality hazelnuts, ensuring that the final product meets the required standards.

· High Efficiency: AI color sorters can operate 24/7, greatly improving production efficiency. Compared with traditional manual sorting, AI color sorters can process large quantities of hazelnuts in a very short time, significantly increasing the speed of the production line.

· Precision: The combination of AI algorithms and machine vision allows color sorters to accurately detect wormholes and other defects, achieving a level of precision far beyond manual sorting.

· Consistency: AI color sorters continuously learn and optimize their performance, maintaining high-accuracy sorting while eliminating inconsistencies caused by human factors, ensuring stable product quality.

· Cost Reduction: With increased automation in production, businesses can significantly reduce labor costs and improve operational efficiency.

The emergence of AI color sorters has revolutionized the hazelnut processing industry, particularly in sorting wormhole hazelnuts. By leveraging precise image recognition and deep learning algorithms, AI color sorters not only enhance product quality control but also optimize production processes, helping businesses stand out in a competitive market. As technology continues to evolve, AI color sorters will demonstrate even greater potential in various industries, supporting the food processing sector in achieving more efficient and intelligent production.